Privacy Overview

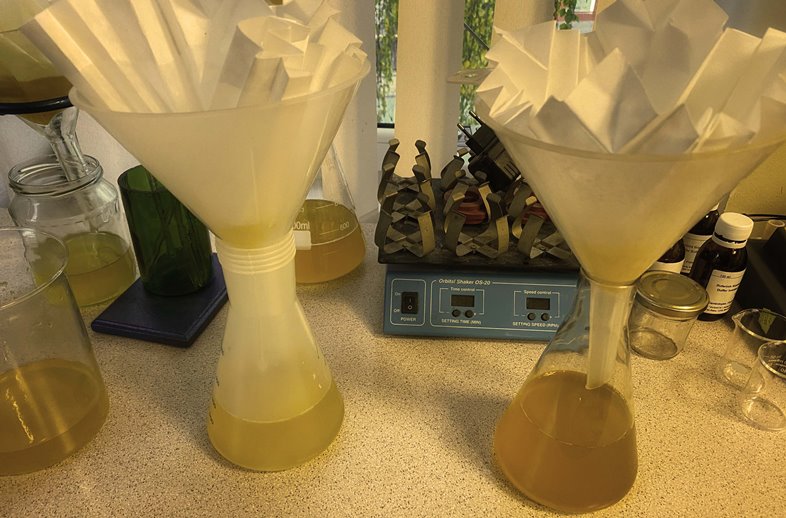

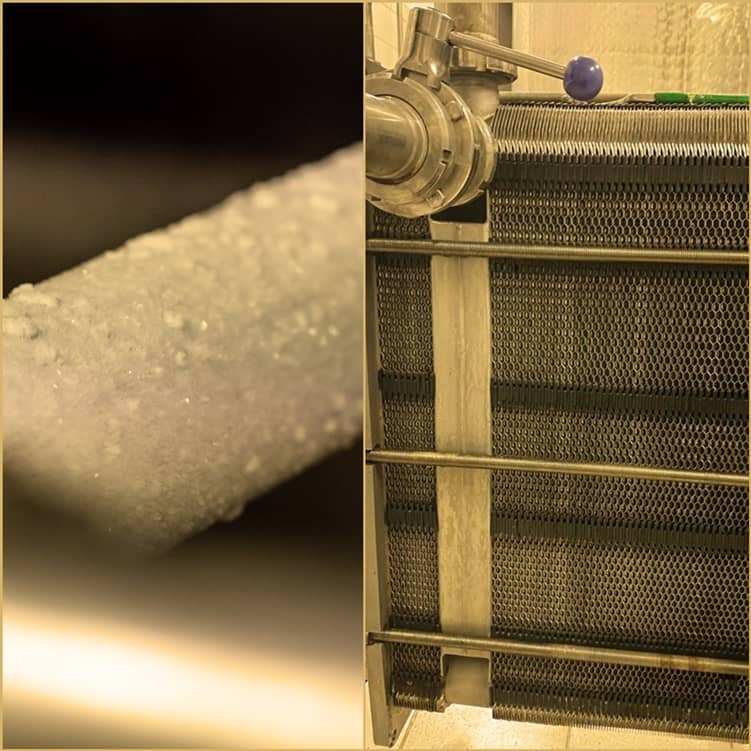

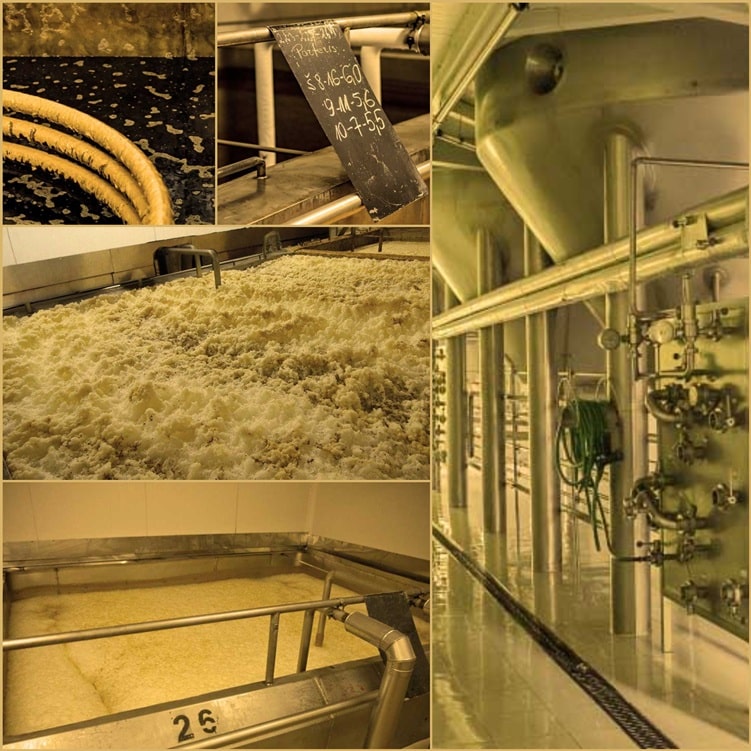

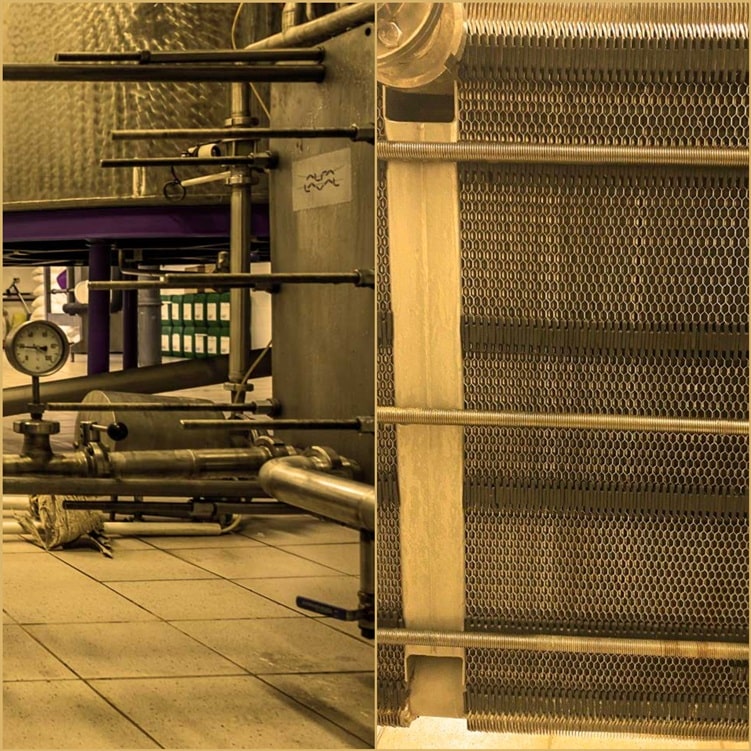

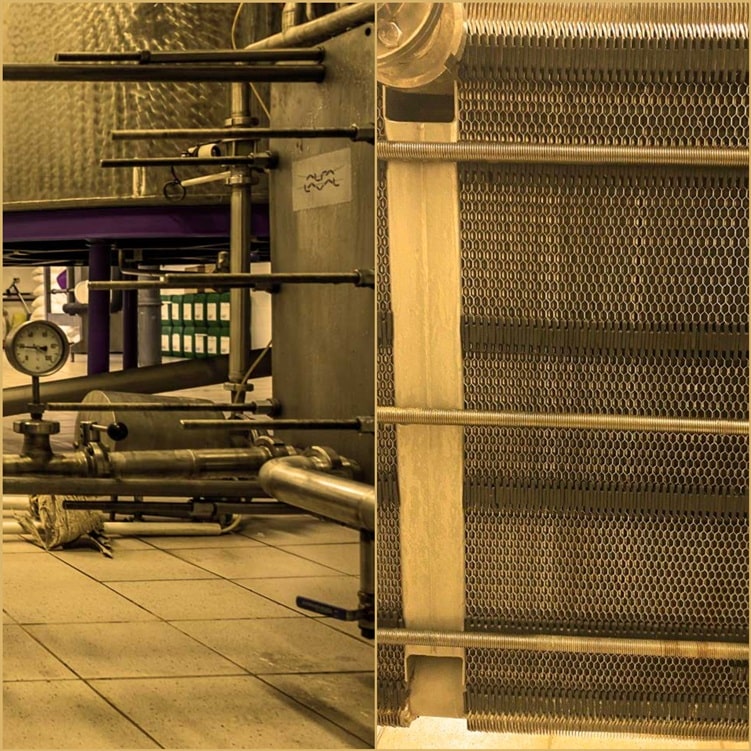

In the refrigerator, the wort is cooled to the temperature required for the fermentation process and then aerated.

Šaldytuve misa atšaldoma iki reikiamos fermentacijos procesui temperatūros ir aeruojama.

Filtered beer goes into the containers where it is kept until it is bottled. Then the beer is poured into the barrels (KEG) and glass bottles. To ensure longer life, beer is pasteurized with a flush pasteurizer and bottled into glass or PET tare.

Beer in barrels (KEG) can be also both non-pasteurized and non-filtered.

Filtruotas alus paduodamas į saikininkus – talpas, kuriose alus laikomas iki pilstymo. Iš saikininkų alus išpilstomas į statines (KEG-us), ir stiklo tarą. Kad užtikrinti ilgesnį galiojimo laiką alus pasterizuojamas sroviniu pasterizatorium ir išpilstomas į stiklo butelius ir PET tarą.

Į statines(KEG-us) alus išpilstomas ne tik nepasterizuotas bet ir nefiltruotas.

Bottled or barreled, the beer is stored in ventilated warehouses, which are protected from the sunlight, the air humidity of which does not exceed 75% and the temperature is 10-20 degrees.

Išpilstytas į prekinę tarą, alus yra laikomas vėdinamuose, nuo saulės spindulių apsaugotuose sandėliuose, kuriuose esanti oro drėgmė ne didesnė kaip 75 proc., o temperatūra 10-20 laipsnių.

The malt is ground in a special wet grinding mill. The malt grains are crushed and mixed with the required amount of water. It is very important to preserve the grain shell, which is later used as natural filtration layer.

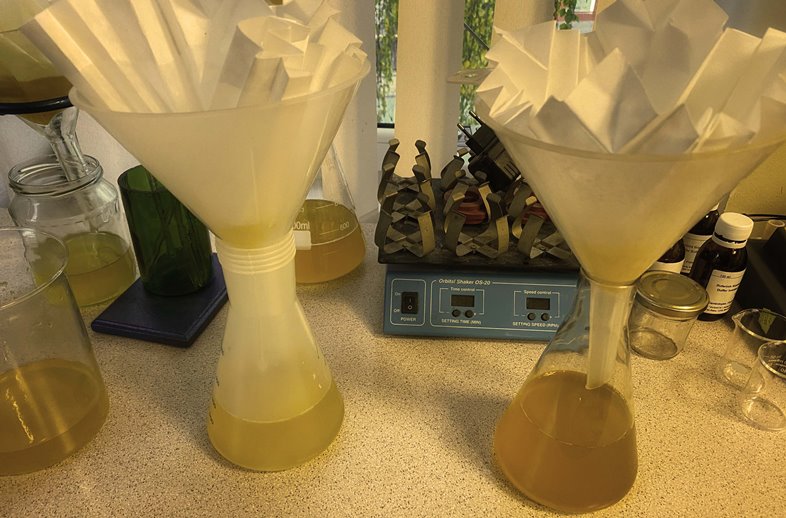

Beer production quality is checked at all technological process stages. Physical-chemical and microbiological analysis is carried out.

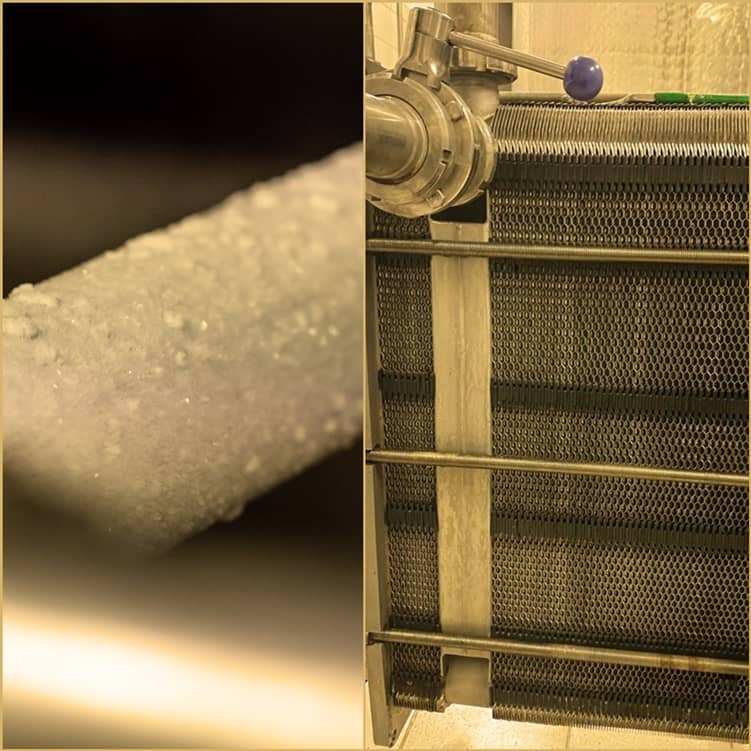

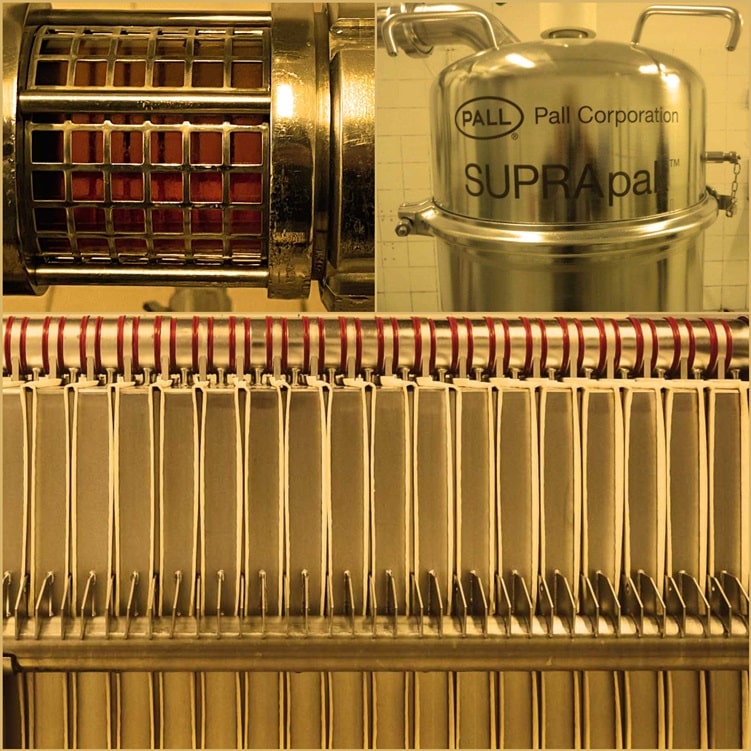

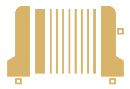

Mature beer is not lucid. In order to remove any beer yeast residues and any other residues, to provide better appearance and stability, the beer is filtered.

During the maturity period, the main beer features are formed: flavor, smell, color, the bitterness and aroma of hops develops and natural carbon dioxide forms. Beer clears and its flavor stabilizes.

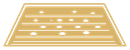

Cool wort is taken to an open fermenting vessel. Beer yeast is added into a flowing wort. During the fermentation process, fermentation sugars turn into ethyl alcohol and carbon dioxide.

From a mash tun, mash goes into a filtration bin where a liquid part – wort – and insoluble parts – draff – are separated. The insoluble wort material forms a natural filtration layer.

Malt is cleaned and any impurity is removed, then it travels into in a wet mill. Milled malt and specially purified water are stirred together until a smooth paste-like material is received, this is called mash. Mash undergoes several processing stages with every stage-specific temperature and time while malt starch turn into fermentation sugars.

Boiled wort is pumped into a precipitation container. There a whirlpool effect is produced, which separates all insoluble particles that have formed a cone. Then wort cools down until it reaches a fermentation temperature and finally it is aerated.

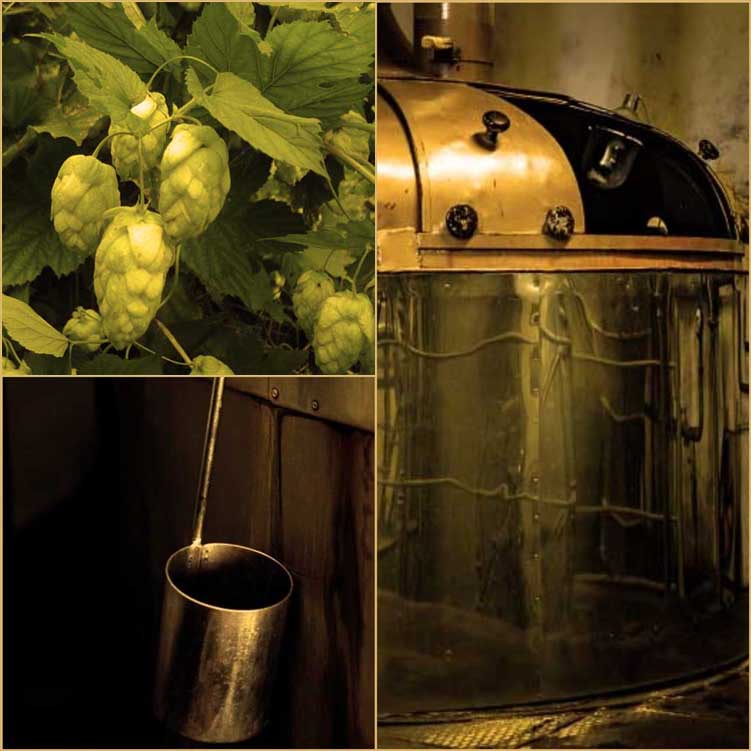

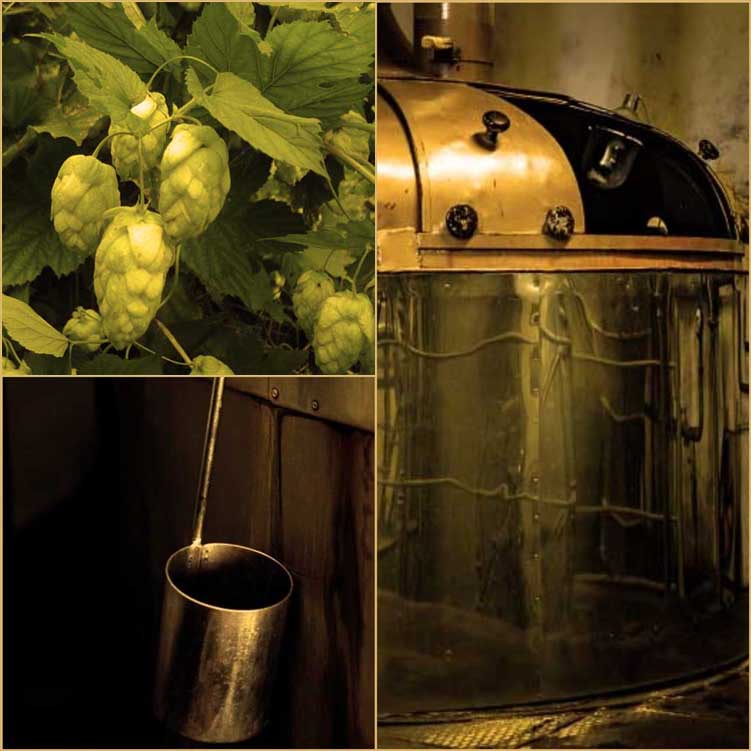

Lucid filtered wort is boiled for 90 min in a brewing kettle. During the brewing process, hops are added: the bitter flavoring is released from the hops, wort takes over the aromatic hop components and any water excess is boiled down.

Skaidri išfiltruota misa yra verdama virimo katile. Į virimo katilą yra dozuojami ir apyniai, kurie suteikia misai aromatą ir kartumą. Taip pat virimo metu misa yra sterilizuojama, išgarinamas vandens perteklius.

Brandinimo metu susiformuoja visos pagrindinės alaus savybės: skonis, kvapas, spalva, išryškėja apynių kartumas ir aromatas, natūraliai formuojasi angliarūgštė. Alus nuskaidrėja, jo skonis stabilizuojasi.

Subrandintas alus nėra skaidrus. Alaus mielių liekanoms, bei kitoms drumstumą sukeliančioms dalelėms atskirti, prekinei išvaizdai suteikti ir stabilumui išlaikyti alus filtruojamas.

Atšaldyta misa paduodama į atviros fermentacijos talpas. Alaus mielės įmaišomos į atitekantį misos srautą. Rūgimo metu fermentuojami cukrūs esantys misoje virsta į etilo alkoholį ir anglies dioksidą.

Išvirta misa paduodama į nusodinimo indą. Jame susidaro sūkurio efektas, atskiriamos visos, į taisyklingą kūgį sušokusios, netirpios dalelės.

Sutraiškytas salyklas užmaišymo katile maišomas su vandeniu, gaunams vienalytė tešlos pavidalo masė-mentalas. Veikiant salykle esantiems fermentams, tam tikroje temperatūroje ir tam tikrą laiką, salyklo krakmolas suskaldomas iki fermentacijai tinkamų cukrų (sacharozė, maltozė).

Salyklas sumalamas specialiame drėgno malimo malūne. Salyklo grūdai yra sutraiškomi ir maišomi su reikiamu kiekiu vandens. Labai svarbu išsaugoti grūdo lukštą, kuris vėliau naudojamas kaip natūralus filtracijos sluoksnis.

Iš užmaišymo katilo mentalas paduodamas į filtravimo katilą, kuriame misa yra atskiriama nuo netirpiųjų grūdo dalių ir lukšto – salyklojų.

Alaus gamyba kontroliuojama visose technologinio prpceso stadijose. Atliekami fiziko-cheminiai ir mikrobiologiniai tyrimai.